From Tools to Techniques: How Metrology Transforms Carpentry Accuracy

Delivering master-class carpentry projects requires precision and excellent knowledge of measurements. Woodwork projects are hinged on the ability to measure and cut with exactitude, ensuring flawless results and a seamless fit. From crafting intricate furniture to constructing stable structures, accurate measurements are the foundation upon which skilled carpenters build their creations.

Precise measurements in woodwork involve a range of essential measuring tools and techniques that enable artisans to achieve remarkable outcomes. These tools, such as tape measures, digital calipers, angle finders, and laser distance measurers, act as extensions of the carpenter's expertise, empowering them to translate their vision into tangible form accurately.

You will acquire the knowledge necessary to undertake your woodwork projects through an in-depth understanding of measurements. Accurate measurements will help you achieve flawless precision and craftsmanship that leaves a lasting impression. Here, we will explore the various types of measuring tools carpenters utilize, gaining insight into their unique applications and best practices for utilizing them effectively.

Understanding Measurements in Carpentry

Metrology refers to the science and practice of precise measurement. It involves using specialized tools and techniques to ensure accurate and consistent measurements throughout the project. The significance of measurements in woodwork cannot be overstated, as it forms the foundation for successful and professional outcomes.

The core principle of measurements lies in achieving accuracy. Carpenters use precise measurements to create components that fit together seamlessly, resulting in aesthetically pleasing and functional structures. From the initial planning stages to the final assembly, every step in joinery demands accurate measurements.

Accurate measurements involve using the right measuring tools for specific tasks. Each tool has its unique purpose, whether it's measuring lengths, angles, or leveling surfaces. From basic tape measures to advanced laser distance measurers, carpenters select the appropriate tool based on the precision required.

By embracing the principles of measurements, carpenters elevate the professionalism of their work. Accurate measurements instill confidence in clients and stakeholders, demonstrating a commitment to quality and precision. Moreover, precise measurements minimize costly errors and reduce the need for rework, saving time and resources.

The Different Types of Measuring Tools

In joinery, precision is paramount. Various measuring tools are essential for carpenters to achieve the desired precision. Here are common measuring instruments:

1. Tape Measure

The tape measure is a basic measuring tool available in various lengths. Its flexible tape, marked with clear graduations, allows carpenters to measure both length and width quickly and easily. To use it effectively, extend the tape smoothly and read the measurements at eye level.

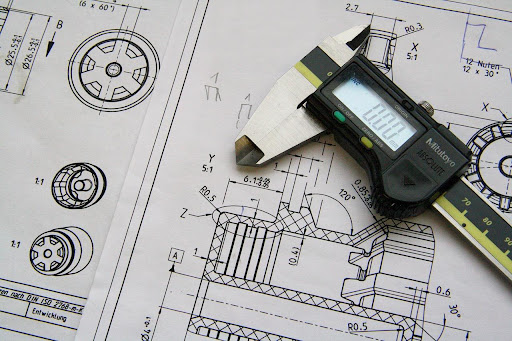

2. Digital Calipers

Digital calipers are precise and easy-to-read tools for measuring small dimensions. They provide accurate readings down to fractions of millimeters, making them ideal for intricate woodwork tasks. Their clear digital display eliminates the need for manual interpretation, ensuring error-free measurements.

3. Angle Finders

Angle finders are indispensable for measuring angles accurately. Carpenters use them to determine angles for miter cuts, bevel cuts, and other angled woodwork tasks. They offer quick and precise angle readings, reducing the guesswork and potential for mistakes.

4. Laser Distance Measurer

A laser distance measurer is a modern marvel in measurements. With a press of a button, it emits laser beams to measure distances accurately. It's especially useful for measuring large areas or hard-to-reach spots, significantly improving efficiency.

5. Level

A level is a fundamental tool for ensuring horizontal and vertical alignments. Whether hanging shelves or installing doors, a level guarantees a straight and balanced result.

6. Combination Square

A combination square is a versatile tool with multiple functions. It serves as a 90-degree angle guide, a depth gauge, and a straightedge. Carpenters use it for layout work, checking angle corners, and transferring measurements precisely.

7. Right Angle Ruler

Also known as a speed square or rafter square, the right angle ruler is indispensable for making quick and accurate measurements. It's commonly used for marking cut lines and checking angles, especially in framing and roofing projects.

The Importance of Accuracy in Woodwork Measurements

Ensuring precision in your woodwork measurements is vital for achieving professional and top-quality results.

1. Professionalism and Craftsmanship

Accurate measurements reflect the mark of a skilled craftsman. Taking pride in your work and producing precise measurements showcases your professionalism and attention to detail. Clients and stakeholders are more likely to trust and appreciate your expertise, leading to a positive reputation in the industry.

2. Project Integrity and Fit

Proper measurements ensure that all components fit together seamlessly. Whether building furniture, installing cabinets or constructing a structure, accurate measurements prevent misalignments and gaps, creating a polished and visually appealing finish.

3. Safety First

Inaccurate measurements can result in hazardous conditions. Ill-fitted pieces may compromise the stability of structures, leading to accidents and injuries. You create a safe working environment for yourself and others by prioritizing precision.

4. Avoiding Costly Rework

Errors in measurements lead to costly rework and material wastage. Accurate measurements save time and resources by reducing the need for re-cutting materials or fixing misaligned elements.

5. Consistency and Reproducibility

Accurate measurements allow you to replicate successful designs. Whether you're producing multiple pieces of furniture or executing similar projects, consistent measurements streamline the process and ensure uniformity.

6. Complying with Building Codes

Woodwork building codes and regulations in many regions enforce specific safety and structural integrity measurements. Adhering to accurate measurements ensures that your woodwork projects meet legal requirements and pass inspections.

7. Longevity and Durability

Properly measured and constructed crafts tend to be more durable. When all elements fit together correctly, the load is distributed evenly, minimizing stress points and increasing the project's longevity.

8. Project Confidence and Peace of Mind

Knowing that you've taken precise measurements gives you confidence in your work. Knowing your project is well-constructed and will stand the test of time instills peace of mind.

Drawbacks of Inaccurate Measurements

Inaccurate measurements in woodwork projects can lead to significant challenges and undesirable outcomes. Understanding these drawbacks is crucial for every carpenter striving to deliver high-quality projects.

1. Compromised Aesthetics and Functionality

When measurements are imprecise, even a minor discrepancy can affect the overall aesthetics and functionality of the project. Crooked lines, uneven angles, and misaligned structures can make the final product look unprofessional and hinder its intended purpose.

2. Wastage of Materials and Resources

Inaccurate measurements often result in material wastage, leading to unnecessary costs and resource depletion. Excess materials used due to incorrect measurements impact the project budget and contribute to environmental concerns.

3. Costly Rework and Delays

Misjudged measurements often require rework, significantly delaying project completion and escalating expenses. The need to correct errors can cause frustration and setbacks for both the carpenter and the client.

4. Safety Hazards

Incorrect measurements pose potential safety risks. Ill-fitting components, unstable structures, and misaligned fixtures can create hazards for occupants and users of the final product. Ensuring perfection in measurements is paramount to maintaining a safe environment.

5. Negative Reputation and Client Dissatisfaction

Woodwork projects marred by inaccuracies can damage a carpenter's reputation and lead to dissatisfied clients. Clients expect professionalism and craftsmanship; inaccurate measurements can erode their confidence in the carpenter's abilities.

6. Legal and Code Compliance Issues

Inaccurate measurements might lead to non-compliance with building codes and regulations. Non-compliance can result in legal repercussions, fines, and even project shutdowns.

7. Time and Effort Wasted

Spending additional time and effort to rectify mistakes takes away valuable resources that could be used for other productive tasks. Precise measurements from the start can save time and streamline the joinery process.

8. Project Disruption

Inaccuracies in measurements can disrupt the entire project flow. One mistake can lead to a domino effect, throwing off subsequent measurements and causing further complications.

To prevent these drawbacks, carpenters must prioritize accurate measuring techniques and invest in quality measuring tools. Regularly calibrating and verifying equipment ensures reliable results. By embracing measurement principles and taking precise measurements, carpenters can deliver exceptional projects that stand the test of time and meet their client's expectations.

Tips on How to Measure Accurately So Your Woodwork Projects Goes Smoothly

Accurate measurements are crucial to the success of any project. To ensure your woodwork projects go smoothly and produce professional results, follow these essential tips and techniques for precise measuring:

1. Marking Techniques

Use the V shape technique to mark your measurements. The technique involves making a small V-shaped notch at the measurement point, providing a more precise and visible reference. Ensure your marking tools are sharp and well-maintained for clean and accurate markings.

2. Standardizing Measuring Tools

Consistency is key, especially when working with multiple team members. Always use the same brand and measuring tools throughout the project to minimize discrepancies and ensure measurement uniformity.

3. Using a Tape Measure Effectively

Master the art of using a tape measure to its full potential. Read the markings accurately, and ensure the tape is flat against the surface for precise measurements. To measure long distances, employ a helper to hold the tape measure steady for increased precision.

4. Mastering Angle Finders

Angles are crucial in joinery, and an angle finder is indispensable. Take the time to learn how to use it correctly, ensuring you can measure and transfer angles accurately for various cuts and joints.

5. Leveling Techniques

A level is your go-to tool for achieving proper horizontal and vertical alignments. Always verify that your level is calibrated correctly and use it regularly during your project to avoid lopsided or uneven structures.

6. Utilizing Digital Calipers

Digital calipers offer unparalleled precision for measuring inner and outer dimensions and depths. Learn how to switch between different units of measurement and take advantage of the "zero" function for differential measurements.

7. Account for Tool Width

When measuring for cuts, consider the width of your cutting tool. For instance, if you need a 10-inch piece, but your saw blade is 1/8-inch thick, measure 10 1/8 inches and make a precise cut.

8. Avoiding Parallax Errors

When using measuring tools with scales or markings, you must read them perpendicularly to prevent parallax errors. A slight misalignment can lead to inaccurate readings.

9. Making Multiple Measurements

Don't rely solely on a single measurement for critical dimensions. Take multiple measurements from different angles and positions to cross-verify and eliminate potential errors.

10. Jigs and Templates

Crafting jigs and templates specific to your project can save time and improve preciseness. These reusable guides help replicate measurements and shapes, ensuring consistency across multiple pieces.

11. Measure Twice, Cut Once

Always double-check your measurements before making any cuts to avoid irreversible mistakes.

12. Keeping Tools Clean and Well-Calibrated

Regularly clean, calibrate, and maintain your measuring tools. Dust, debris, and wear can affect their precision, leading to erroneous measurements.

Practice these techniques, and over time, you'll become a master of measurements. Accurate measurements are the foundation of successful projects, enabling you to achieve professional results and avoid costly mistakes.

Final Thoughts

Measurement is an essential aspect of woodwork that cannot be overlooked. Accurate measurements form the backbone of successful joinery projects, ensuring professionalism, safety, and project integrity.

By understanding the different types of measuring tools, such as tape measures, digital calipers, angle finders, laser distance measurers, levels, combination squares, and right angle rulers, carpenters can choose the right tools for precise outcomes.

Maintaining precision in measurements is crucial. It prevents costly mistakes, ensures components fit together seamlessly, and promotes a safe working environment. Wrong measurements can lead to project setbacks and compromise the overall quality.

To achieve accurate measurements, utilize helpful tips like marking techniques using the V shape, standardizing measuring tools, and mastering the use of tape measures, angle finders, levels, and digital calipers.

Always be aware of the drawbacks of inaccurate measurements, such as rework and unsafe conditions. Learn from professional carpenters who employ pro tips and specialized tools to enhance precision.

In your woodwork projects, remember that every measurement counts. Embrace the principles of measurements and elevate your craft to new heights. Strive for precision, as it is the key to unlocking the true potential of your woodwork projects.